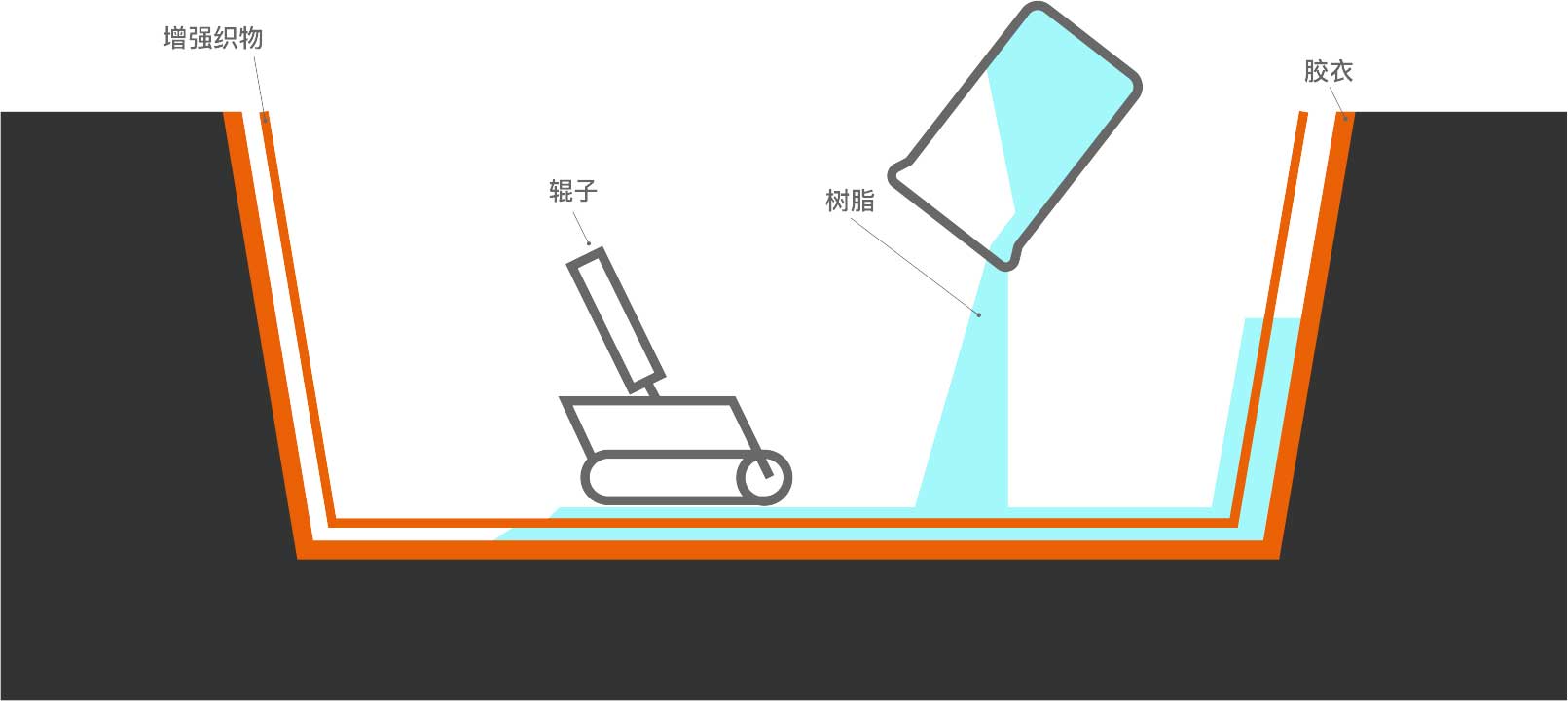

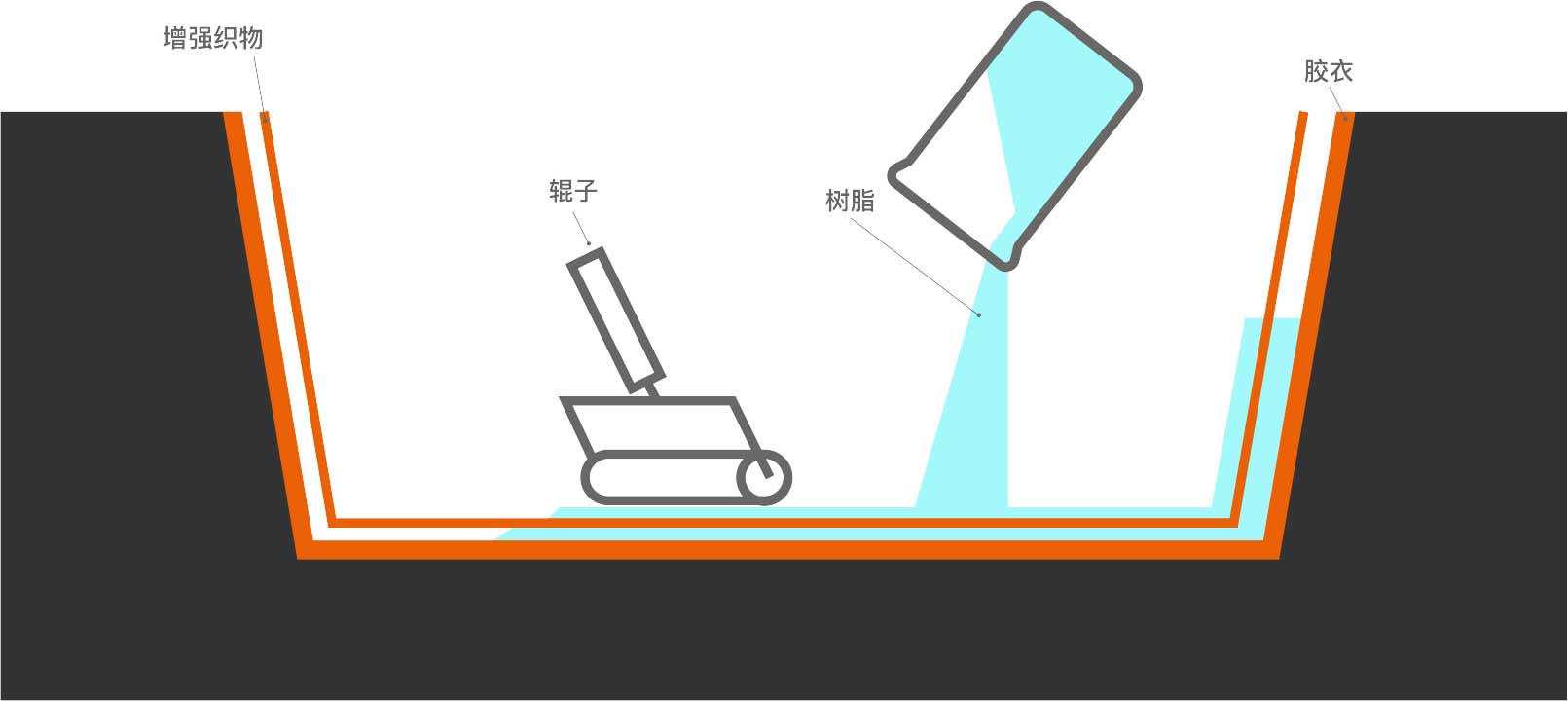

手糊成型工艺又称为低压接触成型,是复合材料工业最早使用的一种成型工艺方法。首先将准备好的模具涂脱模剂,然后将加有固化剂的树脂混合液涂覆到逐层铺覆在模具上的玻璃纤维材料上使其完全浸渍,铺覆到设计厚度,通过固化、脱模形成制品。此成型工艺无尺寸限制,模具材料便宜,在生产大型制品方面仍有一定优势。

相关产品:直接纱 合股纱 多轴向 短切毡 表面毡

Manual moulding process which can also be called low-pressure contact moulding is the earliest moulding process used in composite material industry. First, the parting agent shall be applied on the prepared moulds; then resin liquid mixed with curing agent shall be applied on the fiberglass materials paved layer by layer on moulds to impregnate materials, and the application thickness shall reach the design thickness and moulded products can be formed through solidification and demoulding. This moulding process has no dimension limit and the mould material is relatively cheap, so it has some advantages in large-sized product manufacturing.

Related products: woven fabric, surfacing mat and chopped mat