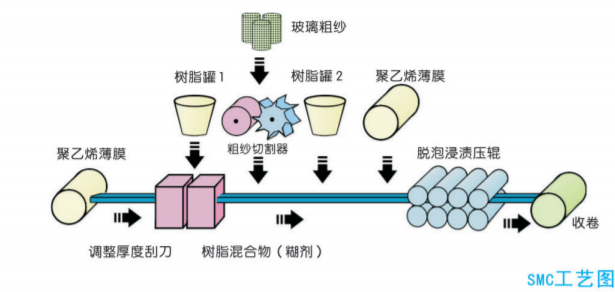

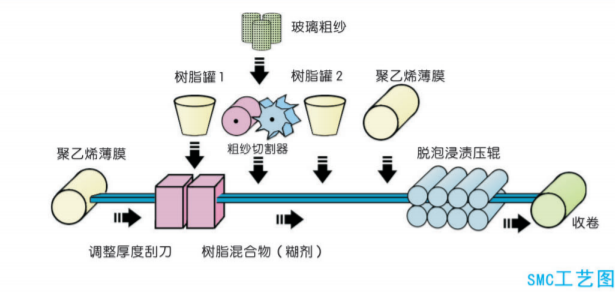

首先制备SMC预浸料,它是用基体树脂(不饱和聚酯树脂)、填料及其他助剂混合成树脂糊,浸渍短切玻璃纤维(从合股纱通过在线切割而来,一般长度为25mm),并且在两面用PE薄膜包覆起来形成的片状模压材料。

再将定量的、揭去薄膜并按照一定形状剪裁的SMC模压料放入金属对模中,在一定温度和压力作用下成型规定尺寸和形状的复合材料制品。

SMC prepregs which are resin pastes made of matrix resin (unsaturated polyster resin), filler and other auxiliary shall be prepared at first to impregnate the chopped fiberglass (cut through wire from multi-end roving and generally the length shall be 25mm), and sheet moulding compound wrapped by PE film on both sides of the glass. The quantitative and SMC moulding materials whose film is ripped off and which are cut in certain shape shall be put into the metal match moulds, and composite material products in stipulated dimension and shape shall be formed under certain temperature and pressure.

Related products: multi-end roving